Collection DB Precast Customized

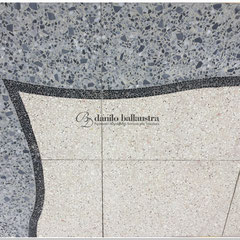

Taking up the "concept" of our DB Precast collection, designed for the customized prefabrications of floors, coverings and furnishing accessories in Venetian Terrazzo, we are able to carry out in our headquarters, even for considerable sizes, all the projects presented to us from every part of the world. After having carried out directly in our production spaces, the phases of installation, sanding and polishing of The Venetian Terrazzo, we proceed to cut on size the large slabs that will cover the surfaces exactly following customer's project.

At the end of this last phase, the slabs will be numbered and loaded in adequate boxes for transport to be made with the most suitable vehicle to reach the site.

Once arrived at their destination, following the numbering assigned to each slab, it is possible to proceed with the installation and reassembly of the floor or the designed covering. This installation can be carried out directly by the company staff that follows the work on site and commissioned by the client or, more accurately, by our specialized staff.

The production of Precast Customized allows shortening the laying time on site, while guaranteeing the highest quality and precision of realization, especially if Venetian Terrazzo is embellished with decorations or designs chosen by the customer.